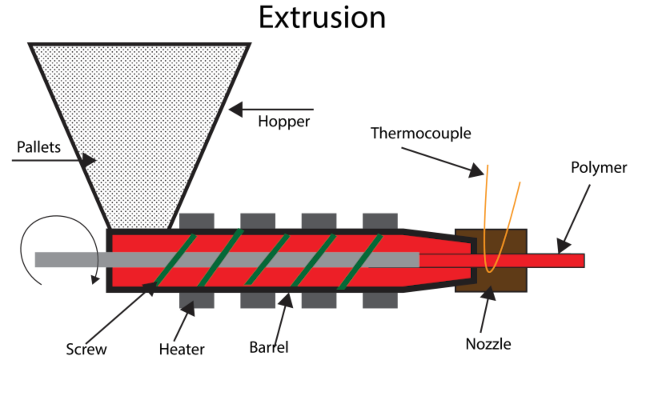

Extrusion Molding

Extrusion is a forming process for thermoplastic. The plastic resin enters the machine via Hopper. Then melted inside the extruder by relying on both heat, shear force and pressure. As the molten plastic flows through the die, it takes on the shape of the die’s openings and exits the extruder. The resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form.

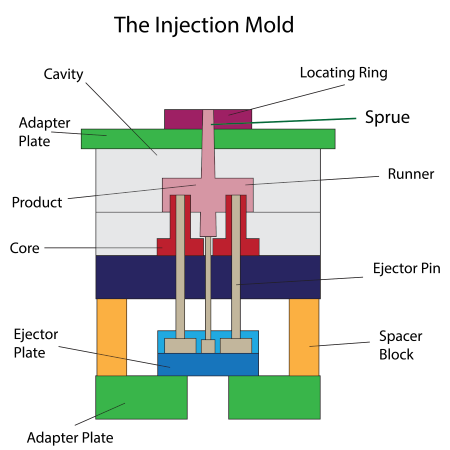

Injection Molding

Injection Moulding process is producing plastic products by inserting the plastic granules, heating them, cooling them and finally giving the shape and size of the required plastic products. It is the rapid method of producing a large number of plastic products with high precision.

Operation process of injection molding

Beginning with plastic beads, it is sent down from the hopper into the syringe. Which has a screw to rotate, take the plastic beads to move to the end of the screw while heating until melting When the liquid plastic at the end of the screw is sufficient. The screw will stop spinning and act as a plastic injector from the nozzle inlet. To the pattern for a short time and provide constant pressure until the plastic hardens. After that, the screws will fall back. The type used will have coolant to cast. To allow the plastic to harden faster. The final type will turn out. The plastic will come out of the form using air or springs to push out.

Thermoforming

Thermoforming is a process that uses plastic sheets or thin films to produce various shapes. This method, the plastic sheet will be burned to the point of weakening and descending until it comes into contact with a vacuum system. Make the plastic sheet come out in shape as it is used.

Operation process of Thermoforming

Start by heating the film. To the point where it starts to weaken (With the temperature depending on each type of film plastic), then use the pressure to press the film to the mold. And use the suction air to attach to the mold, similar to the vacuum cleaner Therefore named Vacuum Forming, the workpiece is released from the print by using a blowout so that the mold-based film does not cause damage from manual sheep.

Molds and Spare part

1. Injection Molding

Injection Molding is Original Equipment of the most common methods of producing parts to supply to the assembly line since the parts from this method could be created with sophisticated details. This type of molding has been widely used in different industries such as electrical appliances, automobiles, household products, packaging, toys, cosmetics, etc.

2. Compression and Transfer Molding

Compression Molding is manufacturing method by putting thermosetting plastic into the mold then the mold would be close by applying high pressure and temperature in order to fill the thermosetting plastic into area of the mold. After that the mold would be cool down in order to let the plastic to set ang from then it would be ejected from the mold.

3. Blow Molding

Blow Molding normally use to produce product with hollow area inside. In general, the workflow would be start with the parison which looks like a stick of plastic into the system then would transfer to the blowing machine to use wind power to blow into the parison according to the designed mold, then the part would be eject from the mold The products in the market that usually produce using the blowing method would be hollow packaging stuff, gallon, bottle, etc.

4. Extrusion

In order to produce products or parts that are either choke or hollow with unlimited length, the extrusion mold often been selected as the method of production. The flow of the extrusion system would start with putting pressure and heat to the resin in order to melt it then it would be injected through the molding to form up as the desired shape.

5. Thermoforming

The production flow of this type of molding is by inserting thin sheet of plastic into the machine, the machine would release heat in order to make the plastic sheet softer, then it would vacuum the soft plastic sheet into the mold to from up as the desire product has been design through the mold. The products that often use this type of molding to make are egg tray, ice cream cup, yoghurt cup, etc.